- Ремонт vector drive haas

- Свяжитесь с нами

- Результаты поиска

- Web Pages

- Images

- Vector Drive — Troubleshooting Guide

- Устранение неполадок векторного привода

- Устранение неполадок векторного привода

- Введение

- Электробезопасность:

- Таблица симптомов

- Thread: Vector Drive Problems!!

- Vector Drive Problems!!

- Re: Vector Drive Problems!!

- Re: Vector Drive Problems!!

- Re: Vector Drive Problems!!

- Re: Vector Drive Problems!!

- Re: Vector Drive Problems!!

- Contact Us

- Search Results

- Web Pages

- Images

- Vector Drive — Troubleshooting Guide — NGC

- Vector Drive — Troubleshooting Guide — NGC

- Vector Drive — Troubleshooting Guide — NGC

- Vector Drive Troubleshooting Video

- Introduction

- Electrical Safety

- Symptom Table

- Ремонт вектор драйв станка хаас

- stanki.tm@yandex.ru

- Работаем по всей России!

- +7 910 822 46 74

- Ремонт промышленной электроники Haas

- Гарантия на выполненные работы

- Время ремонта от 1 дня

- Выезд на предприятие

- Замена оборудования на время ремонта

- получить консультацию специалиста

- Преимущества работы с нами:

- Наши услуги

- Vector-drive HAAS

- Vector-drive FANUC

- Cервоусилители HAAS

- Платы ввода-вывода HAAS

- Запчасти в наличии

- Запчасти для HAAS

- Запчасти для FANUC

Ремонт vector drive haas

Свяжитесь с нами

Результаты поиска

Web Pages

Images

Vector Drive — Troubleshooting Guide

Устранение неполадок векторного привода

Устранение неполадок векторного привода

Введение

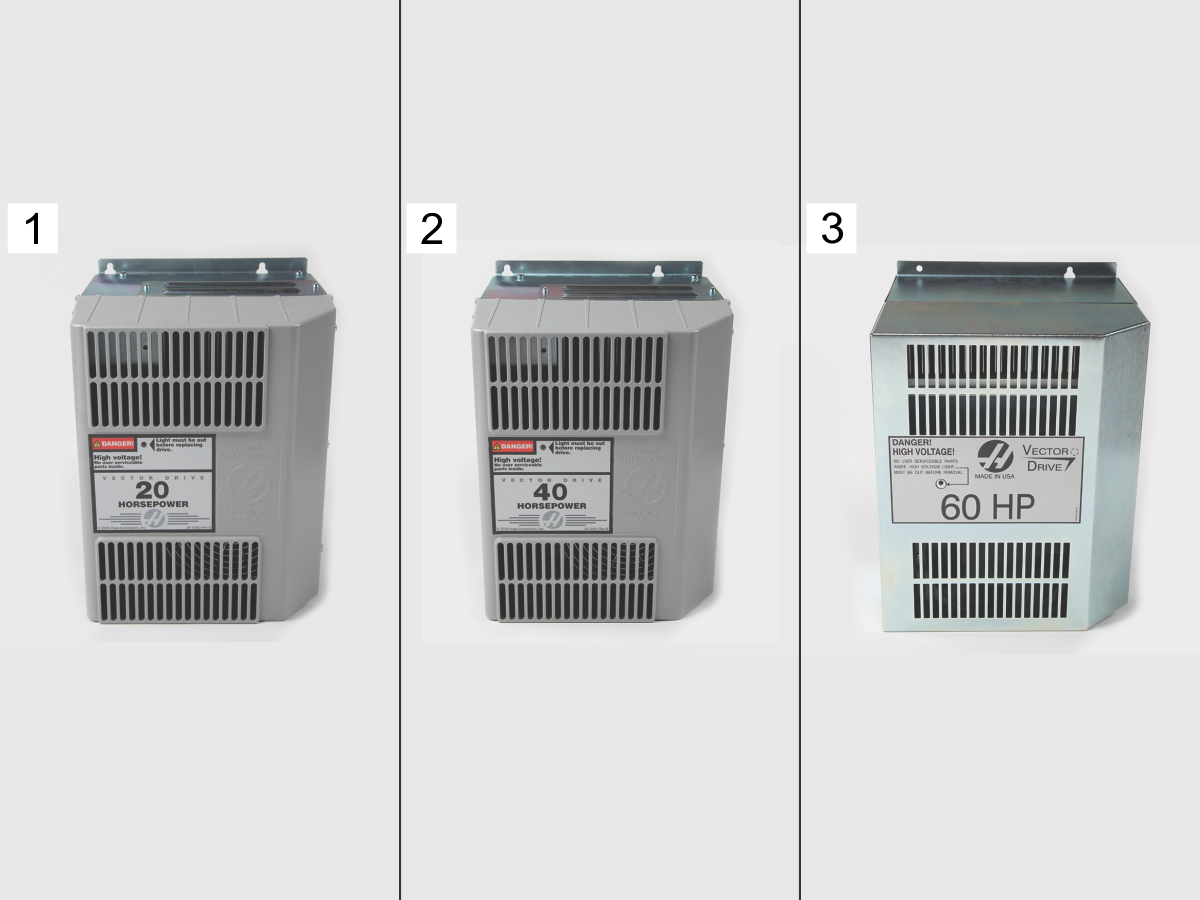

Привод Haas Vector является источником энергии для шпинделя и усилителей сервопривода. Есть три размера дисков Haas Vector: 20HP , 40HP (2) и 60HP (3).

Электробезопасность:

Осторожностью: При техническом обслуживании или ремонте на машинах CNC и их компонентах, вы всегда должны соблюдать основные меры предосторожности. Это снижает риск получения травм и механических повреждений.

- Установите главный выключатель на [OFF] Позиции.

Опасности: Перед началом любой работы внутри кабинета управления индикатор высокого напряжения индикатор аж. 320V Power Supply / Vector Drive должны были выключены, по крайней мере 5 минут.

Некоторые процедуры обслуживания могут быть опасными или опасными для жизни. НЕ пытайтесь процедуры, которые вы не в полной мере понять. Если у вас есть какие-либо сомнения по поводу выполнения процедуры обратитесь в Haas Factory Outlet (HFO) и запланировать посещение службы.

Таблица симптомов

Сигнализации 123 г. SPINDLE DRIVE FAULT и

Сигнализации 993 г. КОРОТКОЕ ЗАМЫКАНИе

Сигнализации 123 г. SPINDLE DRIVE FAULT

НИЗКОЕ НАПРЯЖЕНИЕ ВО ВХОДЯЩЕЙ ЛИНИИ ПЕРЕМЕННОГО ТОКА

Сигнализации 123 г. SPINDLE DRIVE FAULT

НИЗКОЕ НАПРЯЖЕНИЕ ВО ВХОДЯЩЕЙ ЛИНИИ ПЕРЕМЕННОГО ТОКА при власти.

Сигнализации 648 г. АВТОБУС DC КОРОТКИЙ

КАБЕЛЬ УСИЛИТЕЛЯ ОСИ ОТСОЕДИНЕН

Сигнализации 444 г. РЕГЕН ОСТАВАЛСЯ СЛИШКОМ ДОЛГО

Источник

Thread: Vector Drive Problems!!

Thread Tools

Search Thread

Display

Vector Drive Problems!!

Looking for help solving an ongoing problem with many of our Haas machines. Over the last 2 years our company has replaced about 20 vector drives to the tune of $2700.00 each! The alarms produced are all related to either Low DC voltage, Shorted DC buss etc because the control doesn’t see the required 325Vdc buss for the servo drives at the correct level. The problem occurs after the machines have been powered off over a long weekend. All the «tests and checks» required by Haas shows nothing wrong. All voltage levels are correct, no drives are shorted, the only problem is that the signal coming from the Vector Drive itself is not accurate, or takes a very long time to reach a level that the control finds acceptable. If the level is watched (in diagnostics) and it rises above 300VDC, a «quick power cycle» can be performed and the machine comes up alarm free and will run absolutely fine until the next time it is powered down for longer than an hour. In all the cases we have replaced the drive, it was due to a concern that the machine will go down at a critical time and the replacement part will not be on our shelf. I have contacted Haas and they have acknowledged the fact that the problem is as a result of a component failure in the drive. Upon examination of our last failure, I found a small capacitor on the Power PCB inside the drive had burnt/failed. A simple 29 cent parts failure cost our company $2700.00 AGAIN!! Apparently this board ( that Haas Automation stamped on it ) is not available from Haas. I am looking for anyone who can help with suggestions for alternatives to replacing the entire drive. I would think that a company that prides itself on customer service would provide a more cost effective solution to customers who have over 200 of their machines.

Re: Vector Drive Problems!!

You are asking a broad question to a potentially broad problem.

Haas factory? What component? Who diagnosed this?

You have a 10% failure over 2 year period which leads to so many questions.

Is it the same component failure?

If yes, who is diagnosing?

Have you tried having a drive rebuilt by 3rd party vendor?

What is the environment of the machines?

What kind of preventative maintenance is performed?

How hard are the machines run?

How good is the incoming power supply?

What «Tests and Checks» specifically were done?

Do you have internal technitians working on these?

If yes, what are their qualifications?

and on and on and on .

Not saying that you don’t have a problem, but like I said, a broad problem.

Pick one or two machines and discuss specific problems with specific questions, then you may learn the cause to more of your issues. Otherwise you are just talking about geneal issues which leads to a lot of speculation and «what if» scenarios with little productivity.

Re: Vector Drive Problems!!

Thank you for replying to my post. Sorry it has taken so long to reply, I don’t get a chance to check this every day and I’ve been very busy.

To answer your questions, I will try to address them one at a time.

It appears that it is the same component that is failing. I have opened up the last two drives and found the same component, that appears to be a capacitor, on the Power PCB board inside the drive. No attempt to repair it was made and the unit was NOT Attachment 265190sent to a third party repair house. We merely «bit the bullet» and paid for the new drive.

I am a CNC technician with over 30 years experience working on various models of CNC machines.

The environment is clean. No restrictions have been placed on the cooling ventilation system of the drives until lately where we are purchasing the same filter setups used by Haas for the Vector Drive air inlets.

What preventative maintenance should be performed on the Vector drive? I am a Haas factory trained service tech and have used the Troubleshooting Form that has been used by Haas Techs for years. That form, even when used, proved nothing in the past. I am aware that there is a new form, however that form does not explore what the voltage is at P17 on the MOCON or MAINCON boards coming from the drive. In every case of our failures, the voltage at that plug was not representative of what the actual DC buss voltage was.

Incoming power is clean and there are surge suppressors installed on each machine.

Frankly, I understand that in extreme cases a 10% failure would not be an issue. However, 10% failure of a major component such as this, should be considered unacceptable. Especially since the «competition» experiences a fraction of the failures for similar components.

Either the component that is failing is «substandard» in some way, or a Recall of drives manufactured during certain dates should be done. I seem to remember Haas pulling drives manufactured between specific dates off service vans during my career with Haas.

Finally, in my mind, Haas is indeed one of the best CNC machines ever made for «every mans shop». It is hands down, the best «bang for the buck». I would just like to see a more cost effective solution to this problem.

I look forward to your response.

Re: Vector Drive Problems!!

That appears to be a tantalum capacitor and they are known to explode.

As to what else breaks after the cap explodes, or why it exploded.. i couldn’t tell you. that depends on a host of other things.

as to the predictability of tantalum caps exploding.. it follows the 15th power of penny pinching CEO’s. no, i’m not making that up.

Re: Vector Drive Problems!!

Has anyone checked the Regen stack? This can cause pre-mature failures of the Vector Drive. I suggest replacing them and monitoring on a couple of machines.

Also verify grounds at the power panel. Although it may appear that the machine is grounded properly, I have found floating grounds at the breaker box. Try putting in a ground rod next to the machine and re-do the ground cable. This can cause issues as well.

Re: Vector Drive Problems!!

I would personally replace the caps in all the drives. We spent 4 years trying to track down an electric problem that was blowing caps and other electronic components in our machines and the problem turned out to be a power company issue. Suposedly they found a bad neutral somewhere on the grid around us, fixed it and problems gone. If capacitors are blowing consistently then you either have a whole batch of machines with weak capacitors hanging on by a thread or you have a power problem. Capacitors are usually rated for drasticly higher voltage than what they are used at, it takes a serious power spike to blow a perfectly good cap. Id put my money on a power problem or building wiring issue.

Источник

Contact Us

Search Results

Web Pages

Images

Vector Drive — Troubleshooting Guide — NGC

Vector Drive — Troubleshooting Guide — NGC

Vector Drive — Troubleshooting Guide — NGC

Vector Drive Troubleshooting Video

Introduction

The Haas Vector drive is the source of power for the spindle motor and the servo amplifiers. There are three sizes of Haas Vector drives: 20HP [1], 40HP [2] and 60HP [3].

Electrical Safety

Caution: When you do maintenance or repair on CNC machines and their components, you must always follow basic safety precautions. This decreases the risk of injury and mechanical damage.

- Set the main circuit breaker to the [OFF] position.

Danger: Before beginning any work inside the control cabinet the High Voltage indicator light on the 320V Power Supply / Vector Drive must have been off for at least 5 minutes.

Some service procedures can be dangerous or life-threatening. DO NOT attempt a procedure that you do not fully understand. If you have any doubts about doing a procedure contact your Haas Factory Outlet (HFO) and schedule a service visit.

Symptom Table

| Symptom | Possible Causes | Corrective Action |

| The vector drive detected a short circuit. | Inspect the Vector Drive and the Wye-Delta contactors for a short circuit. For Delta-Wye Contactor Troubleshooting refer to: Wye-Delta Contactor — Troubleshooting Guide — NGC. See the Vector Drive short-circuit inspection section below. | |

| There is a problem with the DC Bus. | Compare the measured DC voltage to the Diagnostic page. See the DC BUSS section below. | |

| The vector drive J3 connector inserted upside down. | The old style Vector Drive J3 connector does not have ribs and can be accidentally inserted upside down. This could damage the pins. Correctly inserted, the latch faces away from the Vector drive. | |

| Alarm 647 REGEN LOAD SHORTED | There is a problem with the REGEN. | Measure the resistance across the REGEN leads. See the Regen Load section below. |

| There is a problem with the REGEN circuit on the vector drive. | Check the regen circuit on the vector drive. See the Regen Load section below. | |

| Alarms 9911 AXIS AMPLIFIER CABLE DISCONNECTED | The motor drive cable from Maincon to Amplifier is not connected or has a bad connection. | Check the corresponding axis motor drive cable from the Maincon to the Amplifier and make sure is seated correctly. |

| Alarm 200 HIGH VOLTAGE POWER SUPPLY OVER–TEMPERATURE | There is a problem with the vector drive cooling fan. | Inspect the cooling fan. See the Cooling Fan section below. |